Let’s first cover what a SEG frame is. SEG for short stands for Silicone Edge Graphics. These are fabrics that contain a strip of thin silicone sewn onto the edges of the fabric. On the material, graphics can be printed using dye-sublimated printing. Using the silicone strip, you would insert edges of the fabric into the aluminum frames built-into the SEG frame channel.

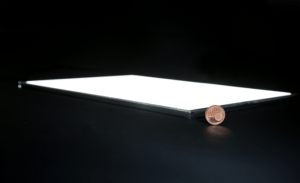

This beautifully ‘mounts’ the graphic onto the frame creating a clean edgeless finish. To take it a step further, ultra-thin LED light guide panels can be incorporated into the SEG frame. By adding the LGP’s, your graphics will stand out due to the LED backlighting.

Let’s now take a look at the top 9 reasons to use SEG frames:

-

Visually Amazing

Due to the dye-sublimated printing process, SEG frame graphics are seen in high-definition quality. The colors are vivid and superbly bring out the natural characteristics of an image or product. There are no white spaces between the pixels giving the print a more visually desirable look.

-

Stand Out

When illuminated, the SEG frame is perfectly even-lit without dark or shadowy spots. This is due to the laser cut and etched LED light guide panel that is used for lighting. Also, the LED colors and brightness can be controlled, and you can set timing schedules using an RGB controller.

-

Easily Swap Out the Graphics

When it comes to updating the graphics, it only takes seconds. No tools are needed, and anyone can do it! Insert the silicone edging into the SEG frame channel, and you are done. The fabric will seamlessly spread across the SEG frame creating the perfect wrinkle-free finish.

-

Completely Adaptable

SEG frames can be custom made to fit any size. They can be mounted flush against the wall or ceiling, used as a tradeshow backdrop, promote new products, used a wall to divide room spaces, and more! The options are unlimited.

-

Save Money

Every time you have a new promotion, want to introduce a new product or share important in-store information, you can use your SEG frame. Print out your unique message on the fabric. You won’t have to purchase an SEG frame or make an alternative to the frame.

-

Save Space

From being ultra-thin at only .61″ in depth to be able to easily uninstall/set-up SEG frames are the perfect solution for spaces that are always changing. The frame its self can be efficiently stored and reused at any time.

-

Simple Installation

Putting together an SEG frame does not require professionals or long periods. Just connect the end connectors by screwing them into place, insert your SEG graphic and you are done. To dismantle, follow the same process but backward.

-

Minimum Shipping Costs

Both the fabric and SEG frames are lightweight and easy to ship. Instead of sending a fully assembled frame, the extrusions can be shipped dismantled. The fabric can be shipped in a tube. This allows for small shipping packages that are easy to ship while reducing your overall costs to ship.

-

Eco-Friendly

The LEDs used for backlighting utilize 70% less electricity when compared to traditional lighting. This reduces the overall carbon emissions while saving you money electric. Also, LED’s last 50,000 to 70,000 hours vs. 15,000 hours of incandescent lighting.

Let’s Collaborate

From pricing to desiging a custom SEG frame around your exact specifications we are here to assist you!

- We offer same day quotes

- Custom SEG frames available

- OEM and wholesale pricing

- Application design support

- Ships from St. Francis, WI

- 2 Year Warranty