How LIGHTPANEL Designs Precision Light Guide Panels

Uniform illumination is the key performance requirement for a high-quality Light Guide Panel (LGP). In architectural, retail, and commercial backlighting applications, even minor inconsistencies such as hotspots, banding, or edge falloff are immediately noticeable and unacceptable.

At LIGHTPANEL, we design Light Guide Panels using a precision-engineered optical approach. Our process combines laser-engraved dot matrices, proprietary pattern control, and integrated thermal management to achieve consistent, even illumination across ultra-thin panels. Energy efficiency has become a fundamental requirement in architectural and commercial lighting, rather than just a bonus.

This article elaborates on how LIGHTPANEL engineers uniform illumination and emphasizes why this approach is essential for demanding backlit applications.

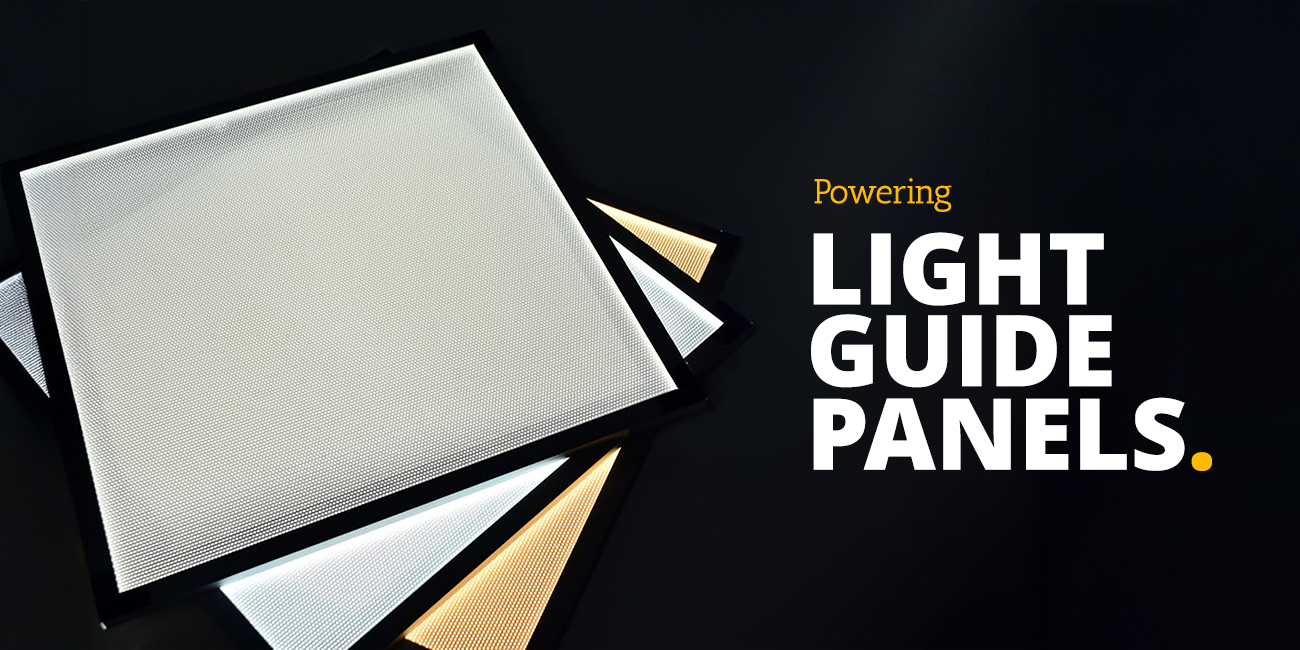

What is a Light Guide Panel

A Light Guide Panel (LGP) is an optical-grade acrylic panel designed to evenly distribute light across a flat surface using LED light sources placed at the edges. Instead of illuminating from behind, light enters the panel at the edges and is internally reflected until it is emitted toward the viewing surface.

The effectiveness of this light extraction affects several key factors:

- Brightness consistency

- Visual comfort

- Material appearance

- Overall system performance

This is where LIGHTPANEL’s engineering approach makes a significant impact.

Laser-Engraved Dot Matrices: The Foundation of Uniform Illumination

At the core of every LIGHTPANEL Light Guide Plate (LGP) is a laser-engraved dot matrix that is etched directly into the acrylic panel. Each dot serves as a precisely controlled light extraction point, redirecting the internally guided light upward toward the surface. In contrast to printed or screened dot patterns, laser engraving provides several advantages:

- Permanent optical precision

- Consistent dot geometry

- High durability over time

- Repeatable performance across panels

LIGHTPANEL uses laser engraving to achieve the level of control required for uniform illumination across large, thin surfaces.

Proprietary Dot Pattern Engineering

Uniform illumination cannot be achieved with a generic dot layout. LIGHTPANEL uses proprietary software and design logic to control various parameters, including:

- Dot size

- Dot spacing

- Dot depth

- Dot shape

The density of the dots is intentionally varied across the panel surface to compensate for natural light loss as it travels away from the LED source. This engineered gradient ensures that there are:

- No bright edges

- No dark zones

- No visible banding or striping

As a result, the illumination is even from edge to edge, regardless of the panel size.

Optical-Grade Acrylic for Consistent Light Distribution

LIGHTPANEL employs optical-grade PMMA acrylic, which has been selected for its:

- High light transmission

- Optical clarity

- Stability over time

- Compatibility with laser engraving

This material allows light to travel efficiently through the panel while ensuring consistent extraction through the dot matrix.

Ultra-Thin Panel Construction

LIGHTPANEL LGP systems are designed to be exceptionally thin, making them ideal for modern architectural and retail environments where space is limited. The ultra-thin construction offers several benefits:

- Sleek, modern designs

- Easy integration into walls, displays, and frames

- Reduced material depth without sacrificing uniformity

However, thinner panels place higher demands on optical precision, making laser-engraved dot engineering essential for maintaining performance.

Integrated Thermal Management with J-Channel Design

Effective heat management is crucial for the long-term performance of lighting systems. LIGHTPANEL incorporates aluminum J-Channel mounting systems that serve multiple purposes:

- Structural support

- LED mounting foundation

- Heat absorption and dissipation

By managing heat effectively, LIGHTPANEL helps to:

- Extend the lifespan of LEDs

- Maintain consistent performance

- Improve system reliability

Thermal management is integrated into the system rather than being an afterthought.

Optical Stack: Beyond the Light Guide Panel

LIGHTPANEL systems utilize a complete optical stack, which may include:

- Laser-engraved light guide panels (LGP)

- Diffusion layers

- Reflective backing

- Protective overlays (glass, stone, acrylic, fabric)

Each layer contributes to smoothing light output and enhancing visual uniformity, ensuring that the final illuminated surface appears clean, consistent, and professional.

Applications That Demand Precision Illumination

LIGHTPANEL Light Guide Panels are ideal for applications where uniform light distribution is critical, including:

- Architectural feature walls

- Backlit stone and solid surfaces

- Retail signage and SEG frames

- Hospitality interiors

- Commercial displays

- Custom illuminated installations

In these settings, uneven lighting can be immediately noticeable, making precision engineering essential.

Why Uniform Illumination Matters

Uniform illumination:

- Enhances the appearance of materials

- Improves visual comfort

- Supports consistent branding

- Elevates perceived quality

For designers, architects, and specifiers, consistent light distribution is a fundamental expectation, not a luxury.

Conclusion: Uniform Illumination Is Engineered

Even illumination does not occur by accident. LIGHTPANEL achieves consistent luminance through:

- Laser-engraved dot matrices

- Proprietary dot pattern control

- Optical-grade materials

- Ultra-thin construction

- Integrated thermal management

This engineering-focused approach ensures that LIGHTPANEL Light Guide Panels provide reliable, consistent, and visually refined results across a wide range of applications.

Work With LIGHTPANEL

Every LIGHTPANEL system is tailored to meet the specific needs of each application, balancing uniformity, form factor, and performance.

Contact LIGHTPANEL to discuss a precision Light Guide Panel solution for your next project.