A Complete Technical & Optical Engineering Guide

Achieving perfectly uniform illumination across surfaces is one of the most essential and technically challenging tasks in LED backlighting. Whether illuminating architectural panels, creating stunning backlit stone displays, captivating retail environments, or enhancing signage and SEG frames, the visual consistency of light plays a pivotal role in both performance and perceived quality.

At the heart of this innovative technology is the laser-engraved dot matrix, a sophisticated optical engine that precisely manages light extraction and delivers uniform luminance across a Light Guide Panel (LGP). This exact mechanism ensures that every inch of the panel radiates light evenly, creating a seamless visual experience.

In this comprehensive guide, we will examine how laser-engraved dot matrices function and explore why they are superior to traditional printed options. We will also delve into how LIGHTPANEL’s engineering expertise creates exceptional luminance, specifically designed for the most demanding commercial and architectural applications, ensuring that every project shines with brilliance and clarity.

What Is a Light Guide Panel (LGP)?

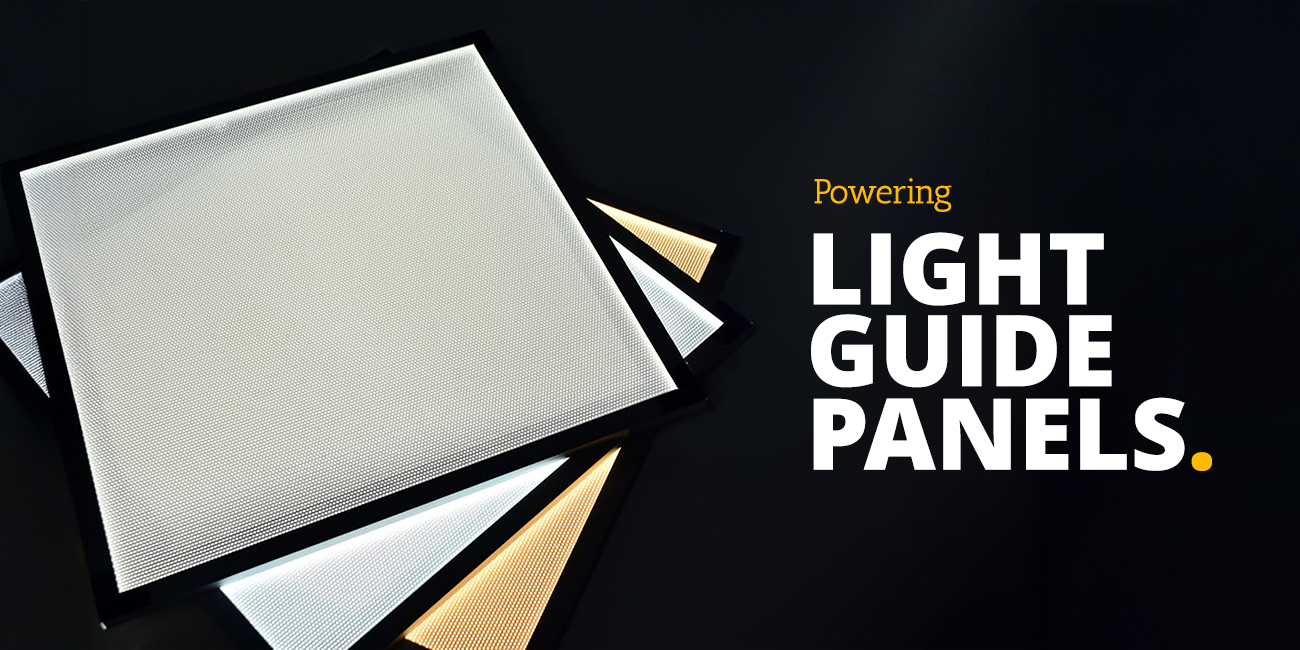

A Light Guide Panel (LGP) is a transparent optical panel typically made from high-grade acrylic (PMMA). Its primary function is to evenly distribute light across a flat surface using edge-mounted LEDs.

Rather than backlighting the panel, the LEDs illuminate its edges. The light then travels through the panel and is extracted upward in a controlled manner. The effectiveness of this light extraction affects several factors:

- Brightness uniformity

- Visual comfort

- Efficiency (lumens per watt)

- Overall appearance of the illuminated material

Light extraction is managed via a dot-matrix pattern.

What Is a Laser-Engraved Dot Matrix?

A laser-engraved dot matrix is a precisely designed pattern of microscopic etched points that are embedded directly into the surface of the Light Guide Panel. Each dot serves as a light extraction point, redirecting internally reflected LED light toward the front surface of the panel.

Unlike printed dots, laser-engraved dots have several advantages:

- They are permanent

- They offer dimensional precision

- They remain optically stable

- They are fully programmable

- The parameters of the dots include:

- Dot diameter

- Dot depth

- Dot spacing

- Density gradient across the panel

These variables work together to control the amount of light extracted at each point on the panel.

The Optical Physics Behind Uniform Luminance

Total Internal Reflection (TIR)

LED Light Panel Functionality

LED light enters the edge of the panel and travels through it by means of total internal reflection. If left unaltered, the light would remain trapped inside the panel.

Controlled Light Extraction

Laser-Engraved Dots:

- Disrupt internal reflection

- Scatter light upward

- Convert guided light into visible luminance

The challenge lies in achieving an even distribution of light across the entire panel.

Why Graduated Dot Density is Necessary

The intensity of light is highest near the LED injection edge and decreases as it moves across the panel. To address this, the dot density is intentionally varied:

- Low dot density near the LED edges

- Higher dot density farther from the LEDs

- This approach ensures a more uniform light output across the panel.

This gradient ensures:

- Consistent brightness from edge to edge

- No visible hotspots

- No dim corners or falloff zones

LIGHTPANEL engineers calculate dot gradients using optical simulation models that account for:

- Panel size

- Thickness

- LED power and spacing

- Injection method (single-edge, dual-edge, multi-edge)

- Final material translucency

How LIGHTPANEL Engineers Dot Geometry

LIGHTPANEL does not utilize generic dot patterns. Each LIGHTPANEL Light Guide Panel (LGP) is engineered based on several specific criteria, including:

- Exact panel dimensions

- Target luminance (cd/m²)

- LED watt density

- Edge injection configuration

- Application requirements

The optimization of dot geometry focuses on:

- Preventing moiré patterns

- Eliminating visible dot artifacts

- Maintaining smooth diffusion

- Maximizing efficiency

This precision is especially critical for thin panels, where optical tolerances are exceptionally tight.

The Complete Optical Stack: More Than Just Dots

Laser-engraved dots are a component of a multi-layer optical system that includes:

- Laser-engraved Light Guide Panel

- High-efficiency diffusion film

- Optional brightness enhancement films (BEF)

- Protective overlay (glass, stone, acrylic, fabric)

The dot matrix controls light extraction, while the films manage light blending. Together, they ensure:

- Uniform luminance

- High visual comfort

- Maximum material clarity

Applications That Require Laser-Engraved Precision

Laser-engraved dot matrices are essential in various applications, such as:

- Backlit stone and marble panels

- Architectural feature walls

- Retail SEG frame lightboxes

- Menu boards and illuminated signage

- Museums and galleries

- Hospitality and luxury interiors

In these contexts, even slight luminance inconsistencies can be easily detected, making precision crucial.

Performance Advantages of LIGHTPANEL Technology

LIGHTPANEL systems offer several key advantages:

- Edge-to-edge uniform luminance

- No LED hotspots

- High brightness with lower wattage

- Long-term optical stability

- Custom engineering tailored to each project

- Ultra-thin panel compatibility

LIGHTPANEL systems are designed for real-world commercial performance rather than just optimal lab conditions.

The Importance of Uniform Luminance

Poor luminance uniformity can result in:

- Distracting hotspots

- Uneven color appearance

- Reduced material clarity

- Decreased perceived quality

In contrast, uniform luminance ensures:

- Visual comfort

- Accurate color rendering

- A premium appearance

- Consistent brand presentation

This is particularly crucial for high-end architectural and retail installations.

Conclusion: Precision Engineering Makes a Difference

Uniform luminance is not a coincidence; it is the result of careful engineering. The laser-engraved dot matrices in LIGHTPANEL enable precise control of light behavior within each panel, ensuring consistent brightness, superior efficiency, and flawless visual results.

When performance, clarity, and reliability are essential, laser-engraved optics set the standard, and LIGHTPANEL is a leader in this field.

Collaborate with LIGHTPANEL’s Optical Engineers

Every LIGHTPANEL system is custom-engineered to meet the specific needs of your application, whether you are backlighting stone, glass, fabric, or graphics.

Contact LIGHTPANEL today to design a precision Light Guide Panel solution tailored for your project.